- SERVICES

Activated Sludge Plant

“Our Activated Sludge Plants use advanced biological processes to treat wastewater efficiently. With reliable aeration and microbial action, they deliver cleaner effluent, meet environmental standards, and provide long-term performance.”

- Biological Wastewater Treatment Systems

Activated Sludge Plant Experts

Reliable Activated Sludge Plant Services

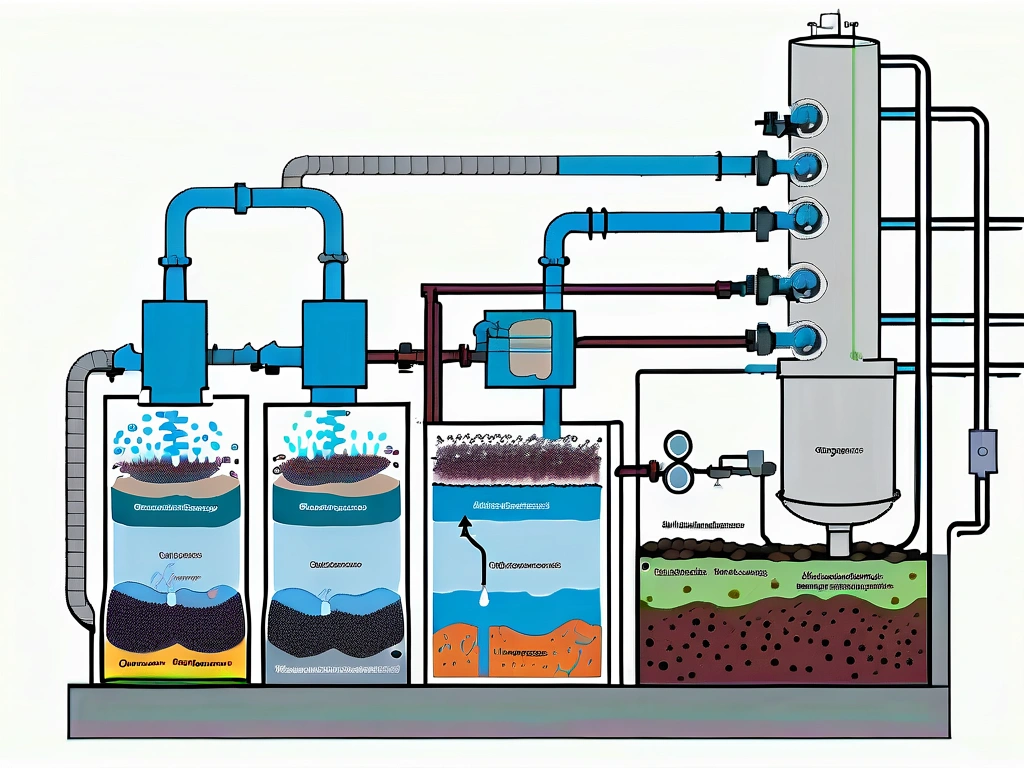

The basic purpose of the activated sludge system is to establish and maintain a viable population of microorganisms by supplying food (BOD5) and the proper environment. In the proper environment, the microorganisms convert the soluble and colloidal material present in the wastewater into new cells (activated sludge) and end products (CO2 and water). During their life cycle, the microorganisms undergo a continuously changing cycle of growth and decline.

This process involves air or oxygen being introduced into a mixture of primary treated or screened sewage or industrial wastewater (called wastewater from now on) combined with organisms to develop a biological mass (aka floc) which reduces the organic content of the sewage. This material is largely composed of bacteria, but also has an important protozoan flora mainly composed of a range of other filter feeding species. In poorly managed activated sludge, a range of mucilaginous filamentous bacteria can develop which produces a sludge that is difficult to settle, and can result in the sludge blanket decanting over the barriers in the settlement tank to severely contaminate the final effluent quality.

The combination of wastewater and biological mass is commonly known as mixed liquor. In all activated sludge plants, once the wastewater has received sufficient treatment, excess mixed liquor is discharged into settling tanks and the treated supernatant is run off to undergo further treatment before discharge. Part of the settled material, the sludge, is returned to the head of the aeration system to re-seed the new wastewater entering the tank. This fraction of the floc is called return activated sludge (R.A.S.). Excess sludge is called surplus activated sludge (S.A.S.) or waste activated sludge (W.A.S). S.A.S is removed from the treatment process to keep the ratio of biomass to food supplied in the wastewater in balance. S.A.S is stored in sludge tanks and is further treated by digestion, either under anaerobic or aerobic conditions prior to disposal.

This process involves air or oxygen being introduced into a mixture of primary treated or screened sewage or industrial wastewater (called wastewater from now on) combined with organisms to develop a biological mass (aka floc) which reduces the organic content of the sewage. This material is largely composed of bacteria, but also has an important protozoan flora mainly composed of a range of other filter feeding species. In poorly managed activated sludge, a range of mucilaginous filamentous bacteria can develop which produces a sludge that is difficult to settle, and can result in the sludge blanket decanting over the barriers in the settlement tank to severely contaminate the final effluent quality.

The combination of wastewater and biological mass is commonly known as mixed liquor. In all activated sludge plants, once the wastewater has received sufficient treatment, excess mixed liquor is discharged into settling tanks and the treated supernatant is run off to undergo further treatment before discharge. Part of the settled material, the sludge, is returned to the head of the aeration system to re-seed the new wastewater entering the tank. This fraction of the floc is called return activated sludge (R.A.S.). Excess sludge is called surplus activated sludge (S.A.S.) or waste activated sludge (W.A.S). S.A.S is removed from the treatment process to keep the ratio of biomass to food supplied in the wastewater in balance. S.A.S is stored in sludge tanks and is further treated by digestion, either under anaerobic or aerobic conditions prior to disposal.

Many sewage treatment plants use axial flow pumps to transfer nitrified mixed liquor from the aeration zone to the anoxic zone for denitrification. These pumps are often referred to as internal mixed liquor recycle pumps (IMLR pumps). The raw sewage, the RAS, and the nitrified mixed liquor are mixed by submersible mixers in the anoxic zones in order to achieve denitrification.