- SERVICES

Intermittent, Bottomless, and Recirculating Sand Filters

- What is a Sand Filter?

There are 3 Types of Sand Filters

ISF

BSF

Bottomless Sand Filter

RSF

Recirculating Sand Filter

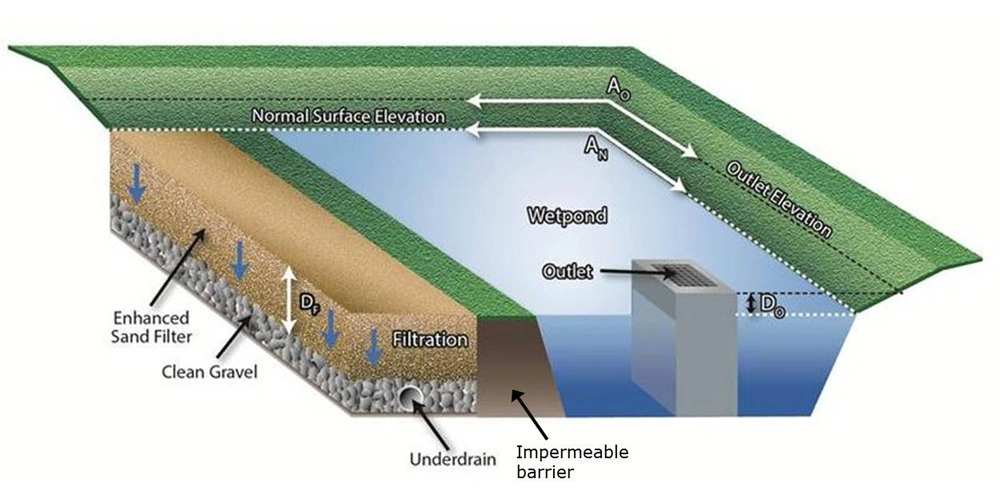

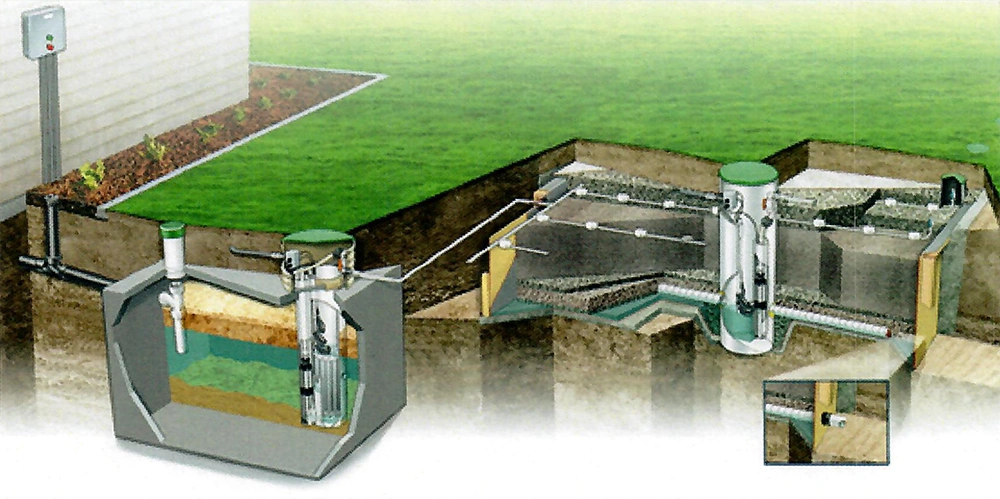

A sand filter is an alternative type of septic system used to pretreat effluent discharged from a septic tank. The sand filter discharges the pretreated effluent to either an absorption field or directly below the sand filter unit itself. A sand filter that discharges effluent directly below the sand filter unit is called a bottomless sand filter. This type of sand filter is only used where rapidly draining soils such as sands or gravels are present. In either sand filter type, a very high quality (clean) effluent is discharged for final treatment in the soil. The sand filter represents a tertiary treatment system where primary treatment of the effluent occurs in the septic tank, secondary treatment of the effluent occurs in the sand filter, and tertiary treatment of the effluent occurs in the soil. The sand filter is used to insure that surface water and subsurface water resources are not adversely impacted by effluent discharges from a residence or a commercial structure. Parcels with soils that evidence high water tables, parcels that have rapidly draining soils overlying shallow water tables, parcels that are in close proximity to surface water bodies or parcels with limited development area are all potential candidates for the use of a sand filter system.

Intermittent Sand Filter (ISF)

Bottomless Sand Filter (BSF)

Recirculating Sand Filter (RSF)

Recirculating sand filters (RSFs) are aerobic, fixed-film bioreactors. Other treatment mechanisms that occur in sand filters include physical processes, such as straining and sedimentation, which remove suspended solids within the pores of the media. Also, chemical sorption of pollutants onto media surfaces plays a finite role in the removal of some chemical (e.g., phosphorus) constituents. Bioslimes from the growth of microorganisms develop as films on the sand particle surfaces. The microorganisms in the slimes absorb soluble and colloidal waste materials in the wastewater as it percolates over the sand surfaces. The absorbed materials are incorporated into a new cell mass or degraded under aerobic conditions to carbon dioxide and water.

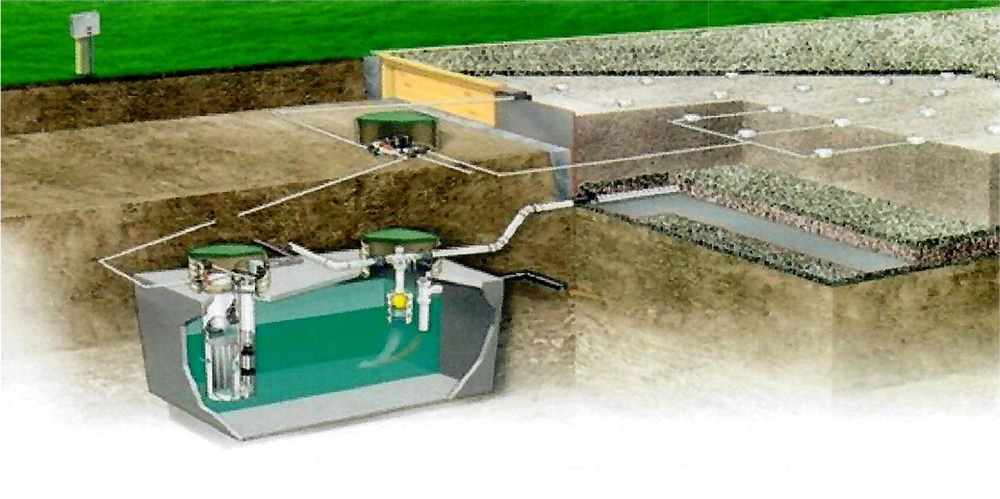

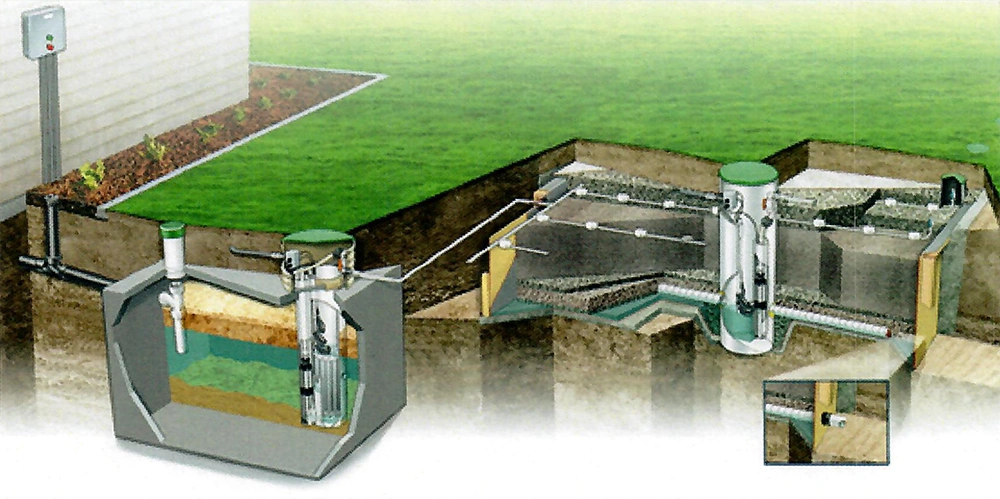

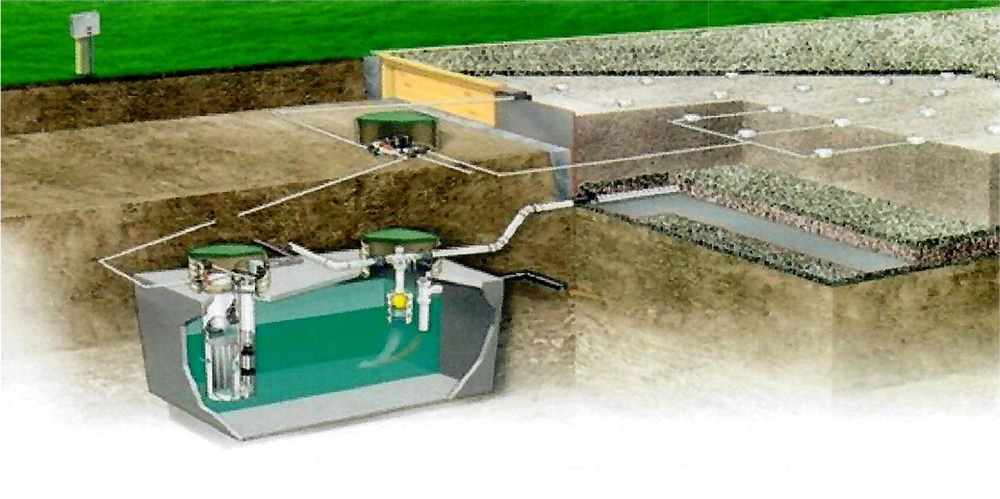

The basic components of recirculating filters include a recirculation/dosing tank, pump and controls, distribution network, filter bed with an underdrain system, and a return line. The return line or the underdrain must split the flow to recycle a portion of the filtrate to the recirculation/dosing tank. A small volume of wastewater and filtrate is dosed to the filter surface on a timed cycle 1 to 3 times per hour. Recirculation ratios are typically between 3:1 and 5:1. In the recirculation tank, the returned aerobic filtrate mixes with the anaerobic septic tank effluent before being reapplied to the filter.